Introduction:

Deep groove ball bearings are essential components in modern industrial settings and play a critical role in numerous mechanical systems. From everyday household appliances to sophisticated industrial machinery, deep groove ball bearings are used across the board to ensure smooth and reliable operation. Whether you're an engineering professional or simply someone intrigued by mechanical principles, this guide will help you learn about the construction, materials, and versatile applications of deep groove ball bearings, along with tips on choosing the right bearing product.

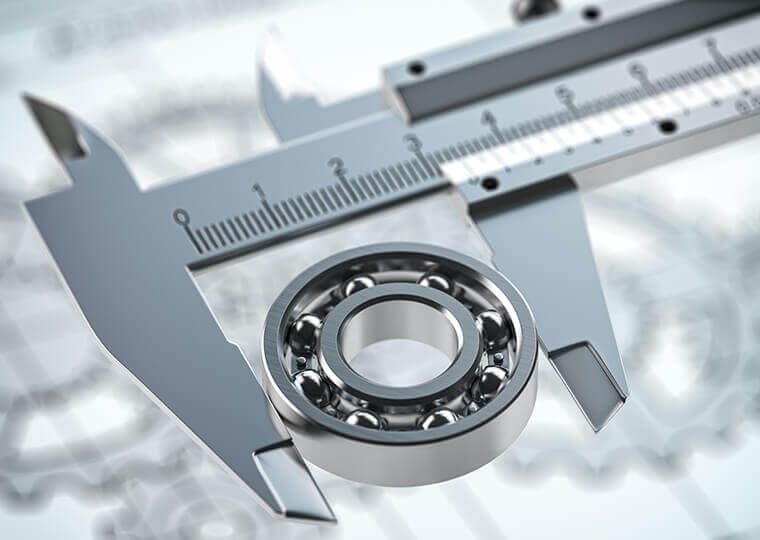

What is a deep groove ball bearing?

A deep groove ball bearing is a widely used rolling bearing characterized by low friction, high speed, and the ability to handle radial loads or combined radial and axial loads. These bearings are commonly used in small power motors, automobile gearboxes, machine tool gearboxes, and general machinery and tools.

Definitions and basic structure

A deep groove ball bearing consists of an outer ring, an inner ring, a set of steel balls, and a cage. Its design enables low friction and high speed, allowing it to handle radial loads or combined radial and axial loads. It can also bear axial loads in certain applications.

Working Principle

Deep groove ball bearings are primarily designed to handle radial loads but can also manage combined radial and axial loads. When subjected to radial loads alone, the contact angle is zero. Bearings with larger radial clearances can handle significant axial loads. These bearings feature a very low coefficient of friction and high limiting speeds, making them ideal for high-speed operations. They are robust and require minimal maintenance.

Types of deep groove ball bearings

There are several types of deep groove ball bearings, including:

Open deep groove ball bearings: These are used to handle radial loads and can also bear smaller axial loads. Their axial displacement is limited to the range of axial clearance, and the inner ring can tilt relative to the outer ring.

Deep groove ball bearings with dust covers: Available in single-sided and double-sided configurations, these bearings have a gap between the dust cover and the inner ring retainer edge. Their rotational speed limits are similar to those of open bearings, but they offer superior sealing.

Deep groove ball bearings with seals: These include single-sided and double-sided sealed bearings. Seals can either contact or not contact the inner ring retainer edge. Contact seals provide excellent sealing but have lower friction resistance and rotational speed limits.

Deep groove ball bearings with stop grooves in the outer ring: This type simplifies axial positioning of the bearing in the housing bore after fitting a retaining ring.

Common materials (steel, ceramics, etc.)

Common materials for deep groove ball bearings include:

Chrome steel: One of the most widely used materials, chrome steel offers excellent wear resistance and high-temperature performance, making it suitable for high-speed and high-load machinery.

Stainless steel: Highly resistant to corrosion and high temperatures, stainless steel is often used in food and medical industries, particularly in wet or corrosive environments.

High-carbon chromium-molybdenum steel: This high-strength alloy steel is ideal for high-load and high-speed machinery, such as automotive and aerospace components.

Ceramics: Materials like alumina ceramics and silicon nitride ceramics are known for their high strength, hardness, and low friction coefficients, making them suitable for high-speed, high-temperature, and high-precision applications.

Plastics: Engineering plastics such as PEEK and PI are suitable for lightweight applications with specific weight and cost considerations.

Properties and benefits of each material

Carbon and Bearing Steels: Carbon and bearing steels (e.g., GCR15 or AISI 52100) are commonly used to manufacture rings and balls for deep groove ball bearings. Heat treatment enhances their strength and wear resistance, making them ideal for high-load and high-speed conditions.

Stainless Steel: Stainless steel materials excel in corrosion resistance and are ideal for wet or chemically corrosive environments. Bearings made from stainless steel can extend service life and reduce maintenance requirements.

Plastics and Ceramics: Engineering plastics and ceramics such as alumina ceramics and silicon nitride ceramics are characterized by high strength, hardness, and low friction coefficients, making them suitable for high-speed, high-temperature, and high-precision applications. Plastics are typically used in light-duty applications, while ceramics are suited for extreme environments.

Accuracy class and tolerance class

Bearing precision refers to the processing errors during manufacturing and is a crucial indicator of bearing performance. It reflects the geometric, dimensional, and rotational accuracy of the bearing. According to ISO standards, bearing accuracy is classified into grades and tolerance systems.

Bearing tolerance refers to the allowable range of deviation between the actual size and the design size of the bearing. The tolerance size directly impacts rotational accuracy, load capacity, and bearing life. Tolerances are typically divided into positive and negative categories; positive tolerances mean the manufacturing size exceeds the design size, while negative tolerances indicate the manufacturing size is smaller than the design size.

Explanation of different accuracy classes

- ISO accuracy classes (P0, P6, P5, P4, P2)

ISO accuracy classes (P0, P6, P5, P4, P2) are established by the International Organization for Standardization (ISO) for bearings and other rotating machinery components. These grades represent the geometric, dimensional, and rotational accuracy of bearings, with P0 being the lowest and P2 the highest.

- ABEC rating system

The ABEC rating system, developed by the American Bearing Manufacturers Association (ABMA) under the Association/Committee for Annular Bearing Engineering (ABEC), evaluates bearing tolerance classes. Primarily focused on precision bearings, including deep groove ball bearings, the system uses numerical ratings (1 to 9), with higher numbers indicating greater accuracy.

- Comparison between ISO and ABEC systems

Both the ISO and ABEC systems are valid standards for evaluating bearing accuracy. However, they differ in terms of the organizations that developed them, their application scope, grade classifications, and numbering methods. While ISO was developed by the International Organization for Standardization, ABEC was formulated by the American Bearing Manufacturers Association. ISO grades are widely applicable to various rolling bearings, whereas ABEC grades were initially designed for skateboarding bearings but have since been applied to precision bearings, especially in the U.S. market. Additionally, ISO grades are expressed in P levels, with smaller numbers indicating narrower tolerance bands and higher precision. Conversely, ABEC grades use numerical ratings, with larger numbers representing narrower tolerance bands and higher precision.

Impact on performance and applications

- Running accuracy

Running accuracy refers to the stability and precision of bearings during rotation. It is influenced by both precision and tolerance. High-precision, small-tolerance bearings ensure higher running accuracy.

- Noise and vibration levels

High-precision bearings generally produce lower noise levels and maintain lower vibration levels during operation. Excessive tolerance can reduce the precision of the fit between rolling elements, inner and outer rings, and other bearing components, leading to uneven clearance and shock vibrations, thereby increasing noise. Both excessively large and small tolerances can result in unstable vibration during bearing operation.

- Heat generation

High-precision bearings require smaller tolerance ranges to ensure stable performance. However, overly narrow tolerances may increase manufacturing difficulty and costs, or lead to excessive assembly stress, accelerating bearing wear and damage. Therefore, when selecting precision and tolerance, it is essential to balance performance, cost, and service life.

- Bearing life

High-precision bearings and appropriate tolerance ranges can extend bearing life.

Deep groove ball bearing applications

Deep groove ball bearings are known for their simple structure, high speed, and low friction coefficient, making them capable of handling radial loads or combined radial and axial loads. Their primary applications are in the automotive and power industries.

Common Uses in Vehicles Stainless Steel Bathtub Faucet

Stainless Steel Bathtub Faucet,Stainless Steel Tub Spout,Stainless Steel Tub Shower Faucets,Stainless Steel Tub Faucet

Heshan Janno Kitchen and Bath Technology Co.,Ltd , https://www.janno-ks.com