Fasteners made from stainless steel offer numerous advantages in terms of manufacturing, performance, and handling. Despite the higher cost and shorter cycle life compared to other materials, stainless steel fasteners remain a practical and economical choice due to their durability and reliability. However, it's important to understand some key characteristics of stainless steel, such as its magnetic properties and the use of nickel in its composition.

One common concern is the magnetic nature of stainless steel fasteners. While stainless steel is generally considered non-magnetic, certain types—especially those in the austenitic series—can become slightly magnetic after specific manufacturing processes. It’s important to note that magnetism alone isn’t a reliable indicator of quality. Some grades, like chromium-manganese stainless steels, are non-magnetic but may not be suitable for high-corrosion environments where 300-series stainless steels are preferred.

Another factor to consider is the use of nickel in stainless steel fasteners. Nickel has historically played a key role in enhancing the material’s corrosion resistance and strength. However, fluctuating global nickel prices have significantly impacted the cost of fasteners. To address this, many manufacturers have started developing low-nickel alternatives, aiming to reduce costs while maintaining performance standards.

As the industry continues to evolve, the search for more cost-effective and sustainable materials remains a priority. Whether through material innovation or process optimization, the goal is to provide high-quality fasteners that meet the needs of various applications without compromising on performance.

If you're looking for more information on stainless steel fasteners, material alternatives, or how to choose the right components for your project, feel free to explore our resources. Stay tuned for more updates on hardware solutions and industry trends.

Tag: Stainless steel fastener, Material, Alternative material, Stainless steel material, Magnetic

Previous: Hardware knowledge: Door lock material knowledge and notes

Next: Purchase steam and water mixing heater precautions

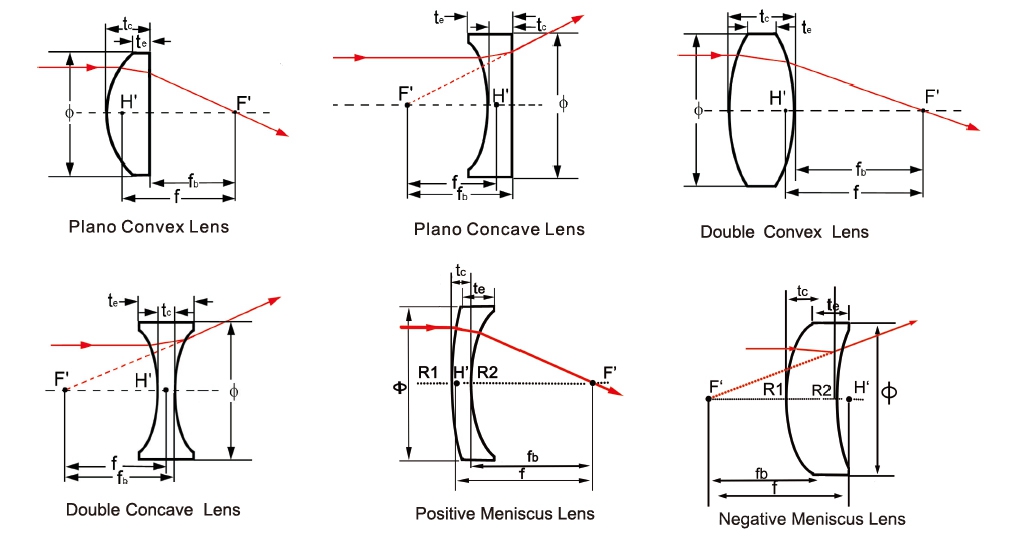

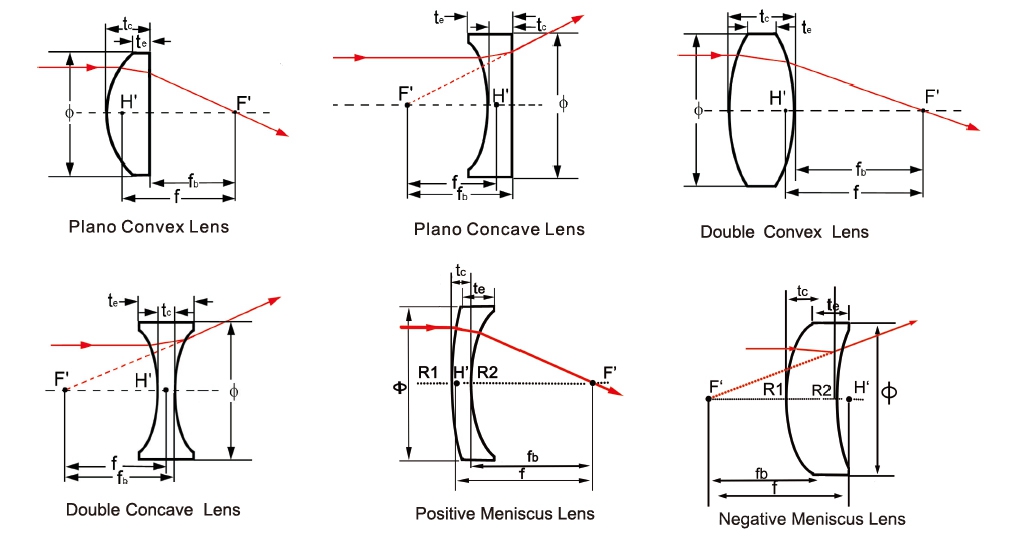

Double-Convex Spherical Lens

Double-Convex Lens, also named Bi-Convex Lens,composing of two convex surfaces, has a positive focal length. DCX Lens is most suitable where the object and image are on opposite sides of the lens and the ratio of the image and object (conjugate ratio) distances is between 0.2 to 5. It is used in beam expanders,projection optics systems, optical viewers applications etc.

We also supply kinds of plano-convex spherical lenses,plano-concave spherical lenses,bi-convex spherical lenses,bi-concave spherical lenses,meniscus spherical lenses,special spherical lenses,achromatic spherical lenses,ball lenses,sphere lenses etc..

Specification of our Spherical Lens as follow:

*Material: BK7,fused silica,MgF2,BaF2,CaF2,ZnSe,ZnS,Ge or other optical crystals

*Dimension Tolerance +0.0 -- -0.1mmÂ

*Center Thickness +/-0.1mmÂ

*Focal Length Tolerance+/-1%

*Surface Quality:60/40Â

*Surface Figure: lambda/2 at 633nm on plano sideÂ

*Clear Aperture >90%

*Chamfer 0.25mm at 45 degree typicalÂ

*Coating : AR coating options available :MgF2, VIS 0°, VIS-NIR, NIR I, and NIR II

Custom Wide Variety of Diameters and Focal Lengths.

Double-Convex Spherical Lens,Double-Convex Lenses,Double-Convex Ar Coated Spheric Lenses,Double-Convex Spheric Lens

China Star Optics Technology Co.,Ltd. , https://www.csoptlens.com