| Home>Bearing knowledge>Application of fine rolling bearings in electronic special equipment |

Application of fine rolling bearings in electronic special equipment

| /*250*250 was created on 2017/12/25*/ var cpro_id = 'u3171089'; |

A: Fine angle touch ball bearing

B: Paired fine angle touch ball bearing set

C: double row cylindrical roller bearing, double direction angular touch thrust ball bearing

D: The normal working time of the tapered roller bearing grease smoothing method is related to the type of bearing and the size and speed. When using the grease smoothing method; pay attention to the selection of the smooth grease type; the calculation and time of loading the bearing cavity smooth grease amount Short low-speed test run. In practice; can not be ignored during the test run; in order to evenly distribute smooth grease and squeeze out too much smooth grease.

Area A: lack of smooth oil; roller elements and tracks do not constitute useful film; T and WF will increase agility. Area B: smooth oil just right; T and WF are the smallest. Area C: added smooth oil; Both T and WF will be added and the addition of T will be more undulating. Area D: continue to add oil; WF will increase; T will slowly decrease after reaching the highest point. The balance between heat dissipation and conflicting force. Area E: Continuously add oil The amount of T will decrease agile after M point; this is because the cooling of oil dominates. B reflects the smoothing method of oil injection; D reflects the smoothness of oil circulation. Pay attention to the method selection when using oil smooth And the viscosity of the oil and the determination of the amount of oil. Should be reasonably selected according to the detailed environment and conditions.

Sealing; it is necessary to use a sealed seal between the inside and the outside when using a fine roll bearing. Consider the following elements; including ambient conditions, smoothing methods, seal wrap speed, seal conflicts, and temperature rise caused by seal conflicts. About fine roll bearings; The two elements are more important. Because the seal conflict is likely to cause heat that the bearing can't bear. Therefore, the high-precision fine rolling bearing often uses a non-rubber seal. The non-rubber seal seal feature is composed of its end cover layout; it can be used for axial, Radial or axial and radial combination conditions. This seal has no conflict and wear. The rubber seal touches the seal appearance; because the conflicting force of the touch causes the temperature to rise; the application of the rubber seal is bound by certain conditions. This method is very Less for fine roll bearing seals, this method is only suitable for low speed conditions. Rubber seals and non-rubber seals are used in combination; can improve sealing effect. In practice; when critical speed is less than 1m/s; can use V-shaped rubber Sealing; the conflicting force that occurs in this application is very good.

3 Application examples because the shaft end jump and the runoff demand are higher; it is medium speed; therefore, the fine angle touch ball bearing is used. The bearing pairing application is divided into two groups; one set is axially fixed; one set is axially outer ring relaxed In order to eliminate the influence of shaft deformation on the normal operation of the bearing due to temperature rise. The placement method is beneficial to improve the stiffness of the shafting and the effect of handling the messy load. The installation spacer is used to achieve the purpose of obtaining the preload. The contact method of non-touch seal and rubber seal is selected, and the grease smooth method is selected to be smooth.

4 Conclusion Fine rolling bearings are widely used in electronic professional equipment. The most important thing in the detailed scrolling shaft drawing is the reasonable use of fine rolling bearings. This paper summarizes several aspects that should be paid attention to in the application of fine rolling bearings; After the use of examples to discuss the concept of the text, fine rolling bearings as long as the correct use; can carry forward its excellent functions.

Recommend to friends comments close window

| Bearing related knowledge |

| The first process of thrust ball bearing installation is detailed. It is easy to distinguish whether NSK imported bearings can be used again. Professor's trick: the layout and characteristics of spherical roller bearings. |

This article links to http://

Please indicate China Bearing Network http://

Previous:Analysis of the Causes of Sintering of Spindle Tiles: The Data Elements Affecting the Life of Bearings and Their Control (1)

Product Description:

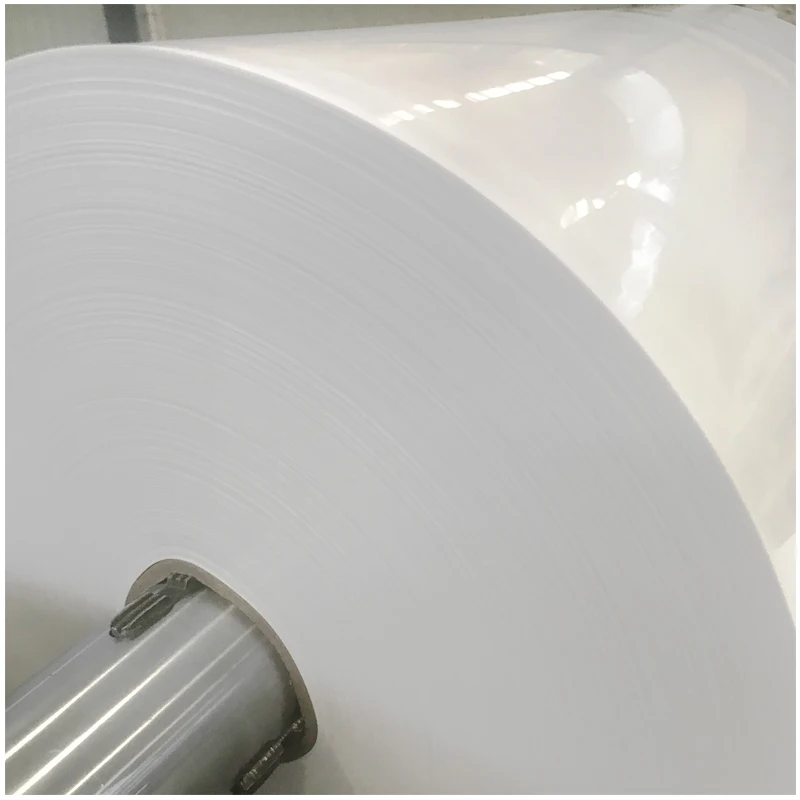

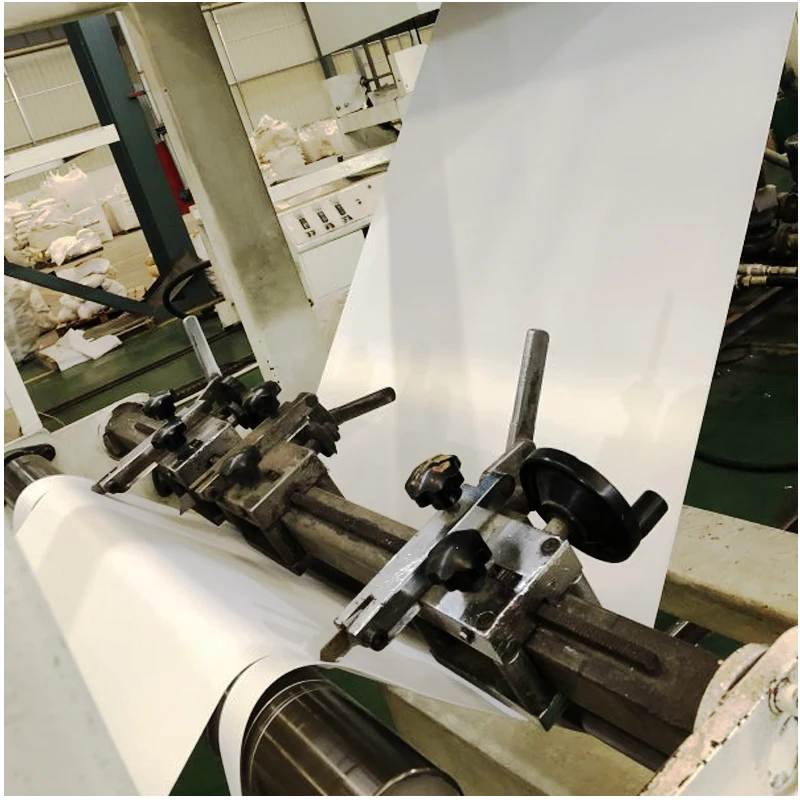

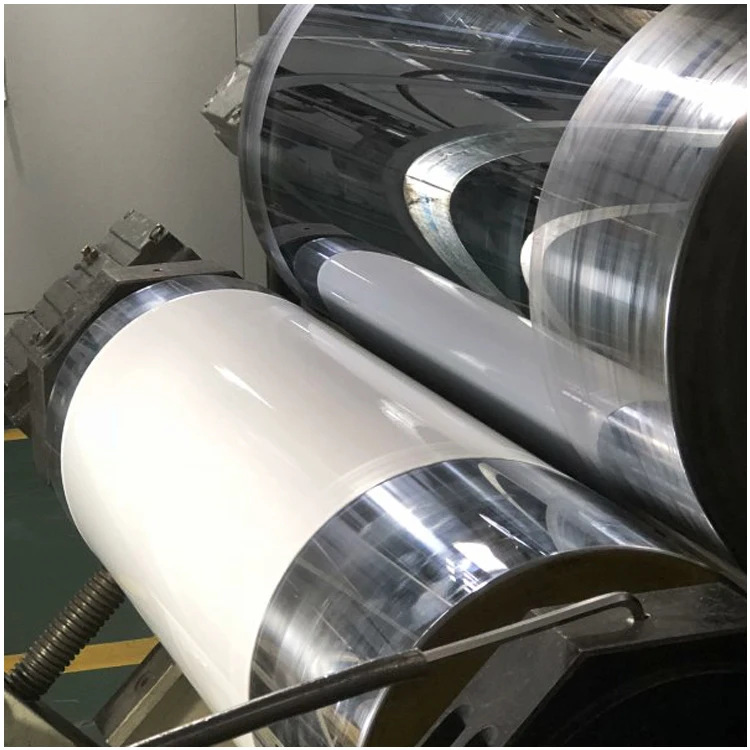

Clear High Impact Polystyrene Plastic Sheet (HIPS) for Vacuum Forming

manufacturer thermoforming rigid Ps Film / white HIPS plastic sheet rolls

High Impact Polystyrene Hips manily to solve the impact brittleness of PS, can be produced different performance and various grades of high impact polystyrene sheet, such as flame retardant grade, high gloss grade, extremely high impact intensity grade and low residual volatile etc.

Our company introduced the newest muli-layer co-extrusion, equipment, could produce , using health grade modified polystyrene, our product conform to government standard, performance PS sheet according to your requirements.

PS applications:

1. blow molding board, CNC engraving materials, laser engraving materials, sign board, light box, window, logo and mark, etc. HIPS also applies to food packaging, milky tea cup lid, moon cake tray, cookies tray. Electronic tray, cosmetics package and other fields.

HIPS Plastic Sheet Features

1. easier process

2. good dimensional stability, high impact strength, high rigidity, heat deflection temperature is 96°, material specifi gravity is 1.05.

3. excellent recovery features, is high quality environmental protection material.

4. Thickness: 0.16-1.5mm

5. Max Width: 900mm

6. Non-toxic and chemical resistant

7. SGS certification and food thickness range0.16-1.5mm

8. natural color, teeth yellow color, coffee color, golden yellow color, brilliant orange color, porcelain white color, black color and all sorts of HIPS sheet.

Packing

Packaging & Shipping for Plastic Sheet:

1. Sample packaging by covered by film or Craft paper.

Delivery

Ps Film,Ps Protective Film,Transparent Ps Plastic Film,Ps Film For Plastic Cup Lids

Shandong Top Leader Plastic Packing CO., LTD , https://www.sdzlplastic.com