The emergence of new materials, advanced manufacturing processes, and cutting-edge technologies has significantly boosted production efficiency, elevated product quality, and driven the hardware industry toward a major transformation. This evolution is not just about improving performance—it's about redefining what hardware can be.

Beyond traditional craftsmanship, many hardware tool manufacturers are now launching innovative product lines that challenge conventional designs. These new products aim to break free from the rigid structures of classic hardware, focusing instead on the harmony between materials, colors, functions, and aesthetics. The result is a more human-centered approach, where form and function work together seamlessly.

Modern hardware is becoming lighter, thinner, shorter, and smaller, all while maintaining strength and durability. Ergonomic design plays a crucial role, ensuring comfort and usability for users. The creative process behind these innovations is bold and daring, blending elegance with practicality. Beyond mere utility, these products now offer an artistic touch, appealing to both functionality and visual appeal.

The development and application of new materials have accelerated the creation of smart, high-performance hardware solutions. With fresh design concepts guiding the way, the new hardware aesthetic is vibrant, dynamic, and full of personality. New materials, advanced techniques, and technological breakthroughs are shaping the true essence of modern hardware.

This trend reflects the broader trajectory of global technological progress. By embracing innovation, industries are not only increasing productivity but also reshaping the way we interact with physical objects. For the hardware sector, these advancements have not only enhanced product quality and functionality but also set new standards, influencing market trends and consumer expectations.

As technology continues to evolve, so too will the hardware industry—driven by creativity, precision, and a commitment to excellence.

The emergence of new materials, advanced manufacturing processes, and cutting-edge technologies has significantly boosted production efficiency, elevated product quality, and driven the hardware industry toward a major transformation. This evolution is not just about improving performance—it's about redefining what hardware can be.

Beyond traditional craftsmanship, many hardware tool manufacturers are now launching innovative product lines that challenge conventional designs. These new products aim to break free from the rigid structures of classic hardware, focusing instead on the harmony between materials, colors, functions, and aesthetics. The result is a more human-centered approach, where form and function work together seamlessly.

Modern hardware is becoming lighter, thinner, shorter, and smaller, all while maintaining strength and durability. Ergonomic design plays a crucial role, ensuring comfort and usability for users. The creative process behind these innovations is bold and daring, blending elegance with practicality. Beyond mere utility, these products now offer an artistic touch, appealing to both functionality and visual appeal.

The development and application of new materials have accelerated the creation of smart, high-performance hardware solutions. With fresh design concepts guiding the way, the new hardware aesthetic is vibrant, dynamic, and full of personality. New materials, advanced techniques, and technological breakthroughs are shaping the true essence of modern hardware.

This trend reflects the broader trajectory of global technological progress. By embracing innovation, industries are not only increasing productivity but also reshaping the way we interact with physical objects. For the hardware sector, these advancements have not only enhanced product quality and functionality but also set new standards, influencing market trends and consumer expectations.

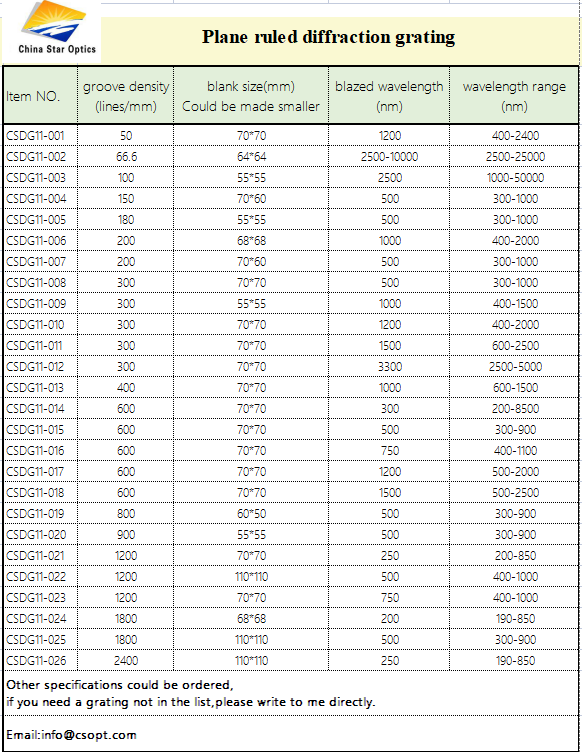

As technology continues to evolve, so too will the hardware industry—driven by creativity, precision, and a commitment to excellence.Plane ruled gratings are characterized by a superior efficiency at their design wavelength compared with holographic gratings. Plane Ruled gratings comprise the majority of diffraction gratings used in spectroscopic instrumentation and are especially useful in systems requiring high resolution.Â

China star optics can provide customers with a variety of replicated grating products such as diffraction gratings, reflective gratings,holographic gratings,concave gratings etc. to meet different needs. Maximum ruled area is up to 300 x 300 mm for plane ruled diffraction gratings. For replicated diffraction and transmission gratings the ruling density can be from 20 grooves per millimeter to 2400 grooves per millimeter, wavelength from 0.2 micron to 25 microns.Â

Holographic gratings:

Specifications:

Ruled area: <=70 * 70mmÂ

Wavelength range: 0.2-0.8umÂ

Grooves per mm: 1,200 to 3,600L/mm

Diffraction: >70%Â

Ruled gratings:

Specifications:

Ruled area: <=70 * 70mmÂ

Wavelength range: 0.2-15umÂ

Grooves per mm: 50 to 2,400L/mmÂ

Diffraction: >70%

Concave gratings:

Specifications:

Ruled area: <=70 * 70mmÂ

Wavelength range: 200 to 900umÂ

Grooves per mm: 490 to 1,200L/mmÂ

Diffraction: >70%

Plane Ruled Grating,Plane Ruled Diffraction Grating,Plane Reflection Grating,Plane Ruled Reflective Grating

China Star Optics Technology Co.,Ltd. , https://www.csoptlens.com